Tel: +86 532-88138566

Fax: +86-532-88138577

Mobile (Whatsapp/Wechat): +86-13792912185

Email: rock@qdantai.com

If the machine is not suitable for your workpiece, please tell us the following infromation:

What kind of workpiece will you clean?

What is the maximum size of the workpiece? (length, width and height)

What is the maximum weight of the workpiece?

What is the cleaning efficiency required?

According to your infomation, the most suitable machines will be designed for your workpieces.

Description

It mainly consists of cleaning chamber, blast wheel assembly, Screw conveyor, elevator, separator, abrasive feeding system and dust collecting system.

The working principle of the rubber belt shot blasting machine is that the specified number of workpieces are added into the blasting chamber. The door is closed. The machine is started and reverses. At the same time, the abrasvies thrown at high speed by the blast wheel form a fan beam,which is evenly hit on the surface of workpieces to clean. The thrown abrasives and sand particles flow from the holes of rubber belt into the screwconveyor at the bottom and are sent into the bucket elevator through screw conveyor, lifted into the separator by the elevator. The dusty air is sucked into the dust collector by the fan and filted to become clean air, which is discharged into the atmosphere. The dust is blown into the dust box at the bottom of the dust Collector, and the user can periodically remove it.The wast sand is discharged from the wast pipe and can be reused by the user. The mixture of the abrasive and sand is recycled into the blasting chamber by the recycling tube, and reused afer separation by the separator.

Appllication range

Suitable for sand cleaning, descaling, oxide skin removal and surface strengthening of small castings, forgings, stamps, gears, springs and heat-treated parts of various varieties, large, medium and small batches. Especially for parts that are not afraid of collision. It's mainly used for foundries,heat treatment plants, motor factories, machine tool accessories, bicycle parts factories, power machine factories, auto parts factories, motorcycle parts factories, non-ferrous metal die casting factories, etc.

Technical parameters

| Item | Unit | Q3210C | 15GN | 28GN |

| Productivity | T/h | 3-5 | 4-6 | 5-8 |

| Max. feeding capacity | Kg | 800 | 1350 | 3500 |

| Max. weight of single workpiece | Kg | 150 | 250 | 360 |

| Diameter of end disc | mm | Φ1000 | Φ1092 | Φ1245 |

| Effective volume | m³ | 0.4 | 0.43 | 0.79 |

| Blasting capacity | Kg/min | 250 | 340 | 480 |

| Air volume | m³/h | 6000 | 6000 | 6000 |

| Power | Kw | 32.6 | 48.5 | 6 |

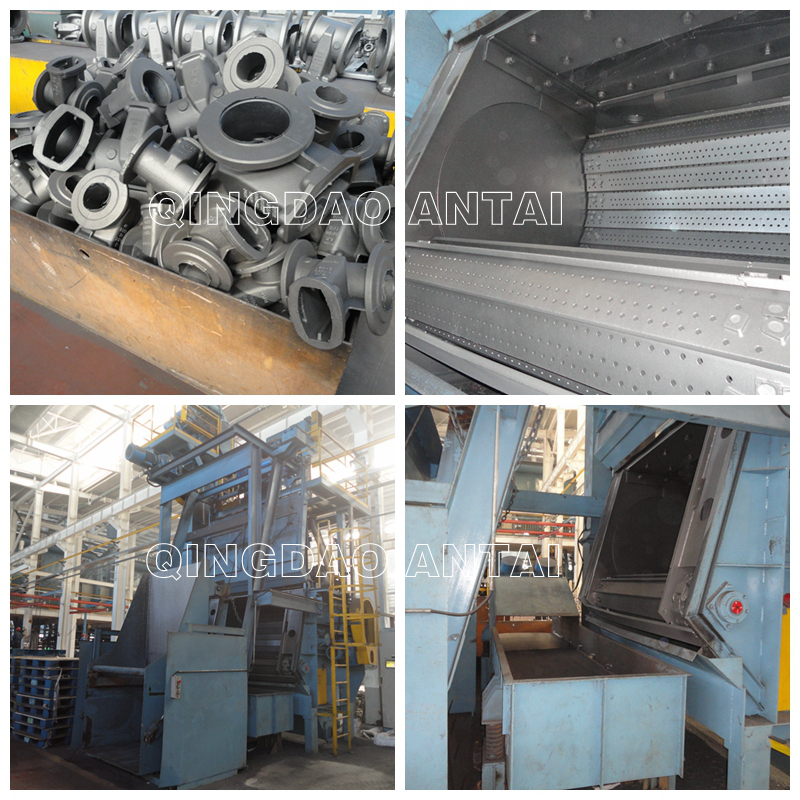

Clean effect and related pictures

1.Large loading capacitycan reach to 3500kgs at a time.

2.No pit design, easy instllation and maintenance.

3.Highmanganese steel belt with service life of 13000 hours.

We guarantee you that we do not store any more data than is required for the services provided. We do not pass this data on to third parties outside the qingdao zhenxiong Mechanical Equipment Co.,Ltd. All information will, of course, be treated confidentially.