Tel: +86 532-88138566

Fax: +86-532-88138577

Mobile (Whatsapp/Wechat): +86-13792912185

Email: rock@qdantai.com

If the machine is not suitable for your workpiece, please tell us the following infromation:

What kind of workpiece will you clean?

What is the maximum size of the workpiece? (length, width and height)

What is the maximum weight of the workpiece?

What is the cleaning efficiency required?

According to your infomation, the most suitable machines will be designed for your workpieces.

Description

The sand blast room is composed of the blasting chamber, air blaster, Abrasive recovery system (scraper mechanical recycling way),screw conveyor, bucket elevator, air wash separator, abrasive feeding system, illumination system, dust collector, trolley system and electric control system.

The sand blasting room is a kind of nonstandard machine equipment and is suitable for surface and inner chamber of large structural parts, box castings, large castings, widely used in ship industrial, military and construction machinery , petrochemical machinery, hydraulic machinery and bridge components , machinery and other locomotives of large metal structures, suitable for sand-blasting and shot peening front surface coating strengthening treatment .

Relying on compressed air as power source, the steel shots are accelerated by the blasting pot to spraying on the surface of work pieces to achieve the purpose of cleaning. After sandblasting able to completely remove the workpiece surface welding slag , rust , oxide skin , oil, etc. , to improve the surface adhesion of the coating to achieve long-term preservation purposes. Furthermore, for shot peening treatment, the surface stress of the workpiece can be eliminated to improve the strength of the workpiece

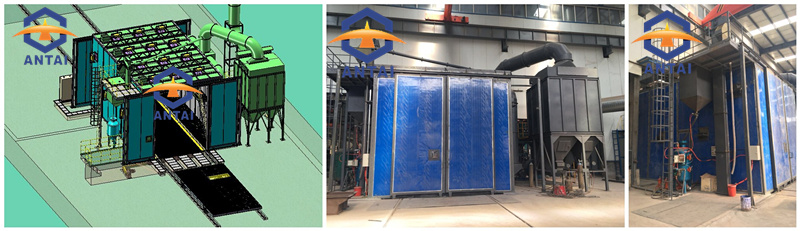

Project pictures

All our products adopts 3D design, More accurate, more intuitive and more convenient for project argumentation and drawing review

Adopting new type scraper conveyor system to collect abrasive, each scraper is driven by a pneumatic cylinder. the depth of foundation is only 350mm, in this case the cost of the foundation can be reduced by 70~80%.

We have sandblasting tank production workshop, all dry type sandblasting pots, dust-free wet type sandblasting tanks are produced by ourselves to ensure the quality of each component. Not buy from outside. The manufacturing technology of the products is very mature, and the sandblasting operation is very stable.

The electronic control system is very important, the whole electronic control system produced by ourselves to guarantee quality. (make programme and assembly).

We guarantee you that we do not store any more data than is required for the services provided. We do not pass this data on to third parties outside the qingdao zhenxiong Mechanical Equipment Co.,Ltd. All information will, of course, be treated confidentially.